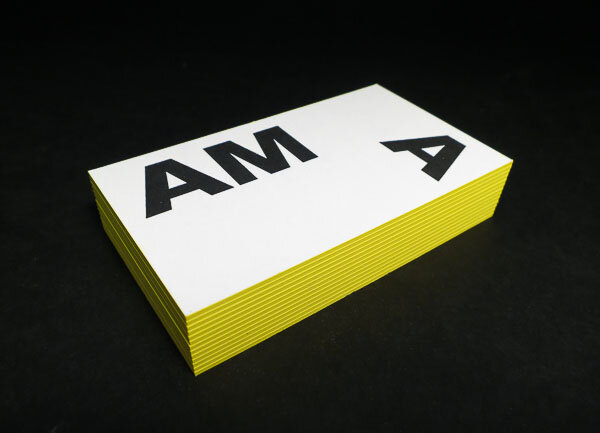

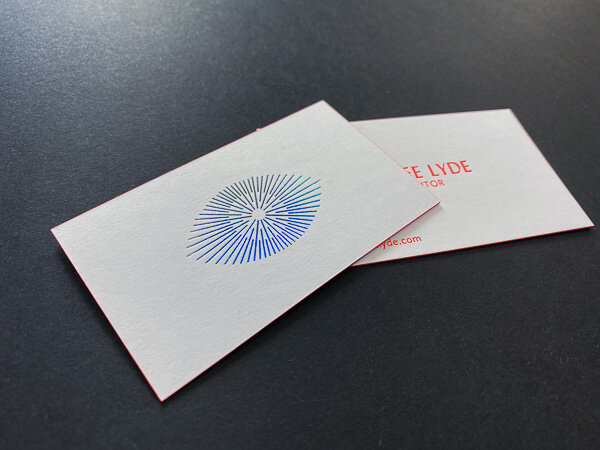

Letterpress Printing

At Publicide, we're not just pressing ink into paper; we're pressing forward into the future. Forget what you thought you knew about this age-old technique. We're redefining the game with the finest materials and equipment available.

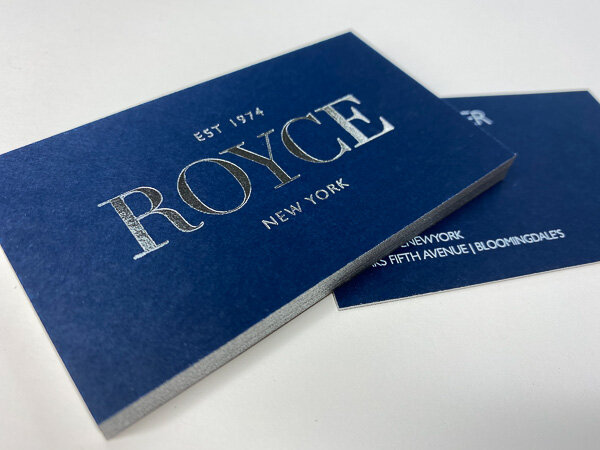

We specialize in razor sharp detail (down to .25pt line weight) and adjustable pressure, from the kiss to practically pushing out the back. No polymer plates here, our copper plates are the epitome of precision, etched to capture every intricate detail. And our inks? Only the best and hand-mixed for the perfect color match.

Sure, we respect the tradition, but we're obsessed with what's next for Letterpress. We're talking about a tactile experience that's not just luxurious but revolutionary. This isn't your grandma's stationery; it's the business card that lands the deal, the invite that becomes a keepsake, the print that turns heads and sparks conversations.

So, if you're looking for Letterpress Printing that's not just pressed but impressive, let us help out with your next project. Welcome to the future of Letterpress.

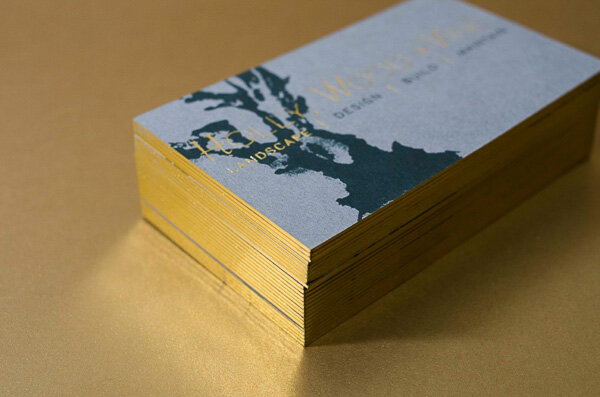

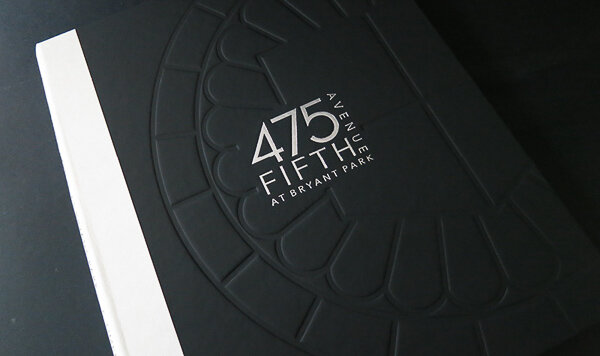

Embossing

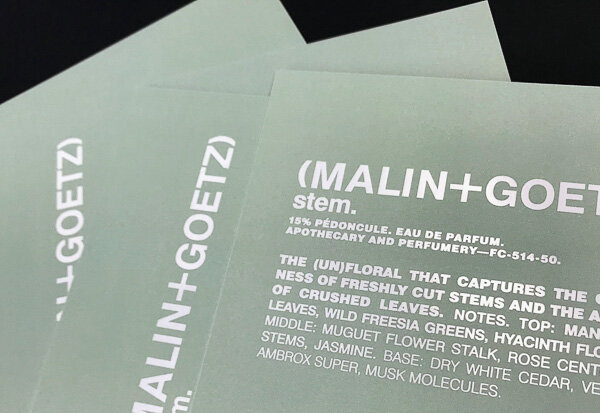

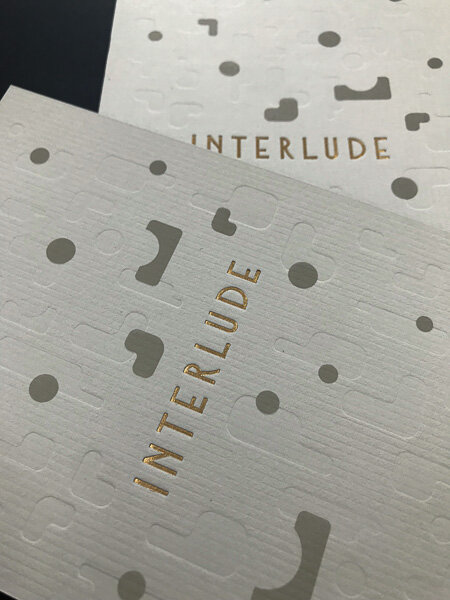

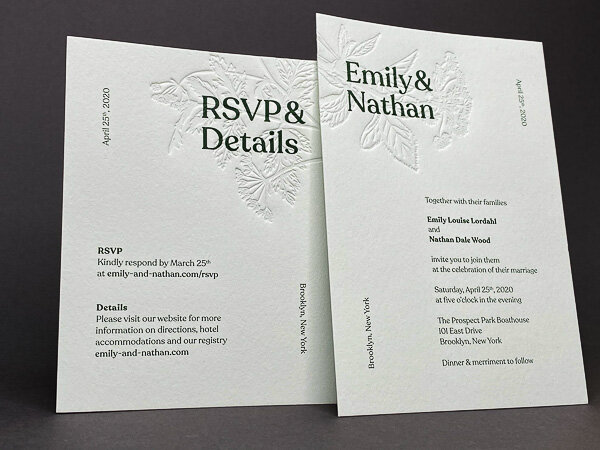

We elevate Embossing to a precise science, merging artistry with engineering for a tactile experience that's second to none. We offer both single-level and sculptured embossing, each with its own set of technical specifications and aesthetic outcomes.

Single-level embossing creates a uniform, raised surface, ideal for adding subtle texture and depth to your printed materials. For those seeking a more complex tactile experience, our sculptured embossing utilizes varying levels of relief to create a multi-dimensional effect, akin to a topographical map.

The key to our unparalleled precision lies in our choice of materials. We employ copper or brass plates, known for their durability and ability to capture intricate details. These plates are meticulously crafted to ensure that each embossed element is sharp, consistent, and perfectly aligned.

Whether you're producing business cards, invitations, or specialized print materials, our embossing techniques offer a tactile dimension that engages. The result is not just a printed piece, but a tactile object that invites interaction and leaves a lasting impression.

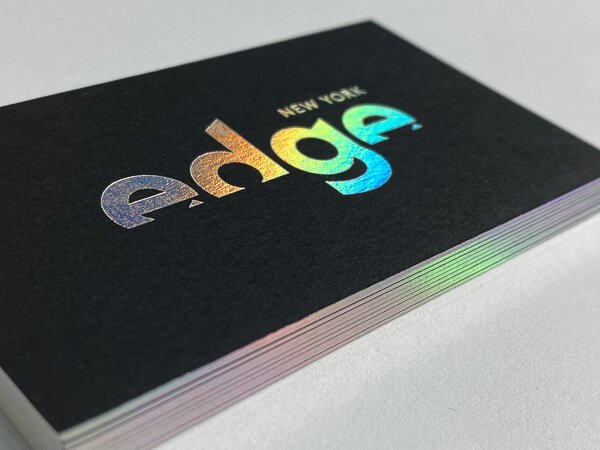

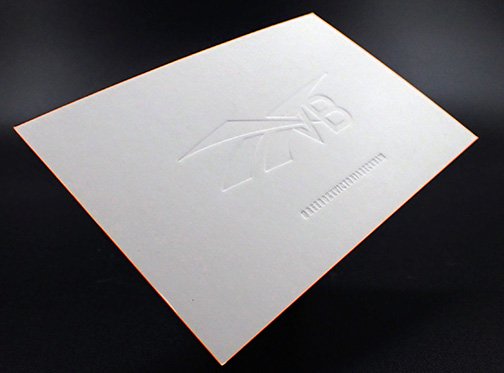

Debossing

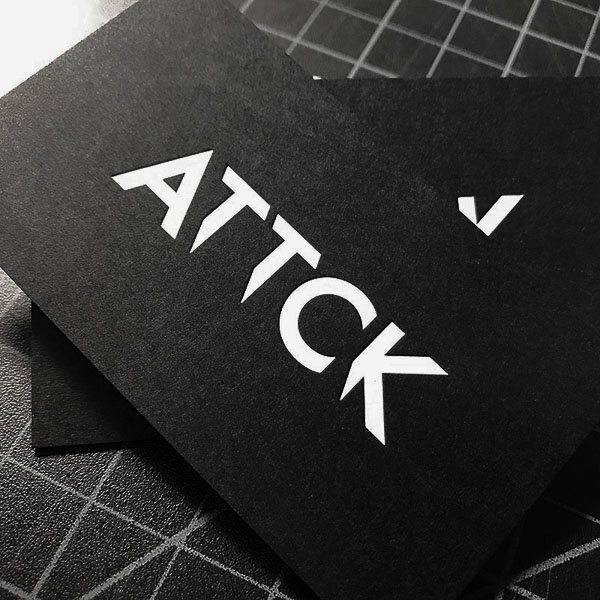

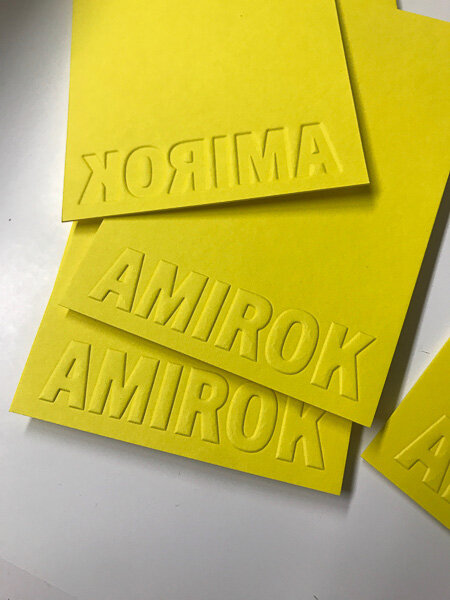

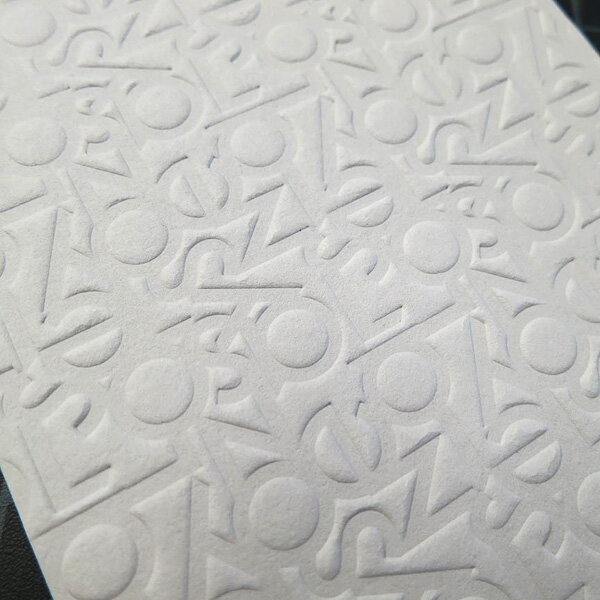

Debossing stands as the counterpoint to embossing, offering an inverse tactile experience by creating indented impressions on paper or other materials.

Debossing compresses the material to create recessed relief. This results in a subtle, yet impactful, indentation that can be felt and seen, adding a layer of sophistication to your print projects. The technique is particularly effective for highlighting logos, text, or other design elements, making them focal points without overwhelming the overall design.

Opt for debossing when you're seeking a subtle yet effective way to add texture and dimension to your print projects. It's a technically refined process that offers a unique sensory experience, enhancing the overall impact of your printed materials.

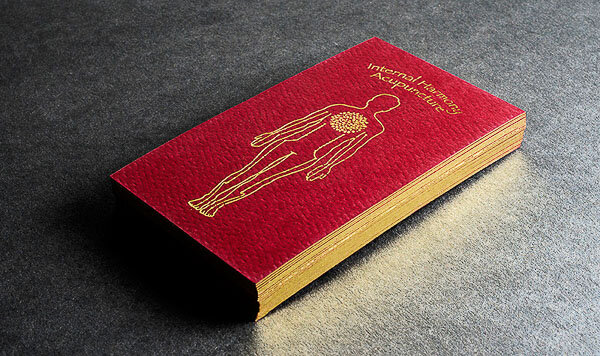

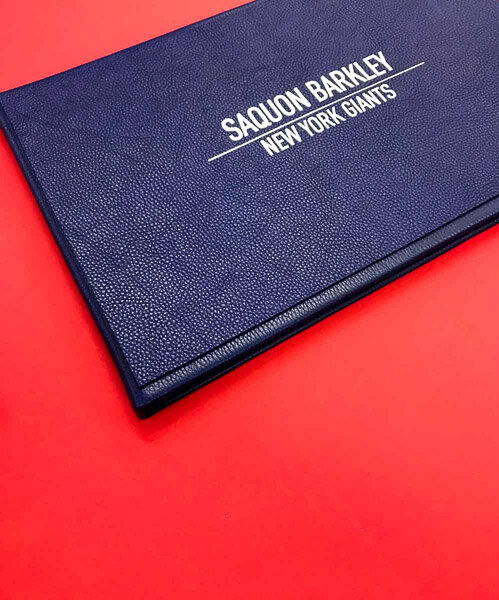

Leather Stamping

Transform book covers into tactile works of art with Leather Stamping. Specializing in both foil stamping and debossing on leather, we elevate the aesthetic of any hardcover or softcover book.

Our process begins with the selection of premium leather materials, sourced in the Garment District of NYC. chosen for their durability and texture. The result is a leather-stamped book cover that not only looks stunning but feels so luxurious to the touch.

But we don't stop with leather. Our expertise extends to silk screening and printing on linen and cotton bookcloth, as well as meticulous attention to the book's pages and bindings. Every element is crafted to meet fine-art standards, transforming each book into a masterpiece in its own right.

Choose our Leather Stamping services for book covers that combine technical precision with artistic flair, setting your publications apart in a competitive market.

More Printing Techniques